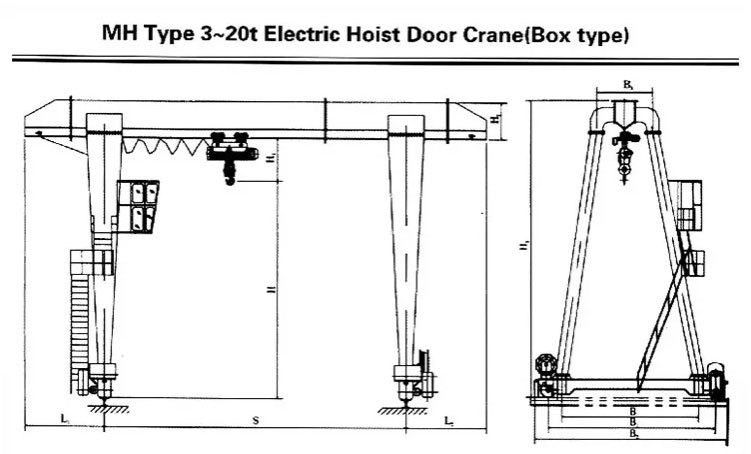

Description

MH type electric hoist gantry crane is used together with CD MD model electric hoists. It is a track traveling small and medium-sized cranes. Its proper lifting weight is 5 to 20 tons. The proper span is 12 to 30 meters, its proper working temperature is -20°C to 40°C.

Working Condition

1. Metal structures and mechanical parts should have sufficient strength, stiffness and buckling resistance.

First of all, it is required that parts and metal structures are not damaged after being loaded. For parts such as steel wire ropes with complex stress states, static strength calculations are usually performed with a higher safety factor based on the main load and main deformation form. It must also be required that the deformation of the component under load is within the allowable range, that is, it should have sufficient stiffness.

2.The whole machine must have relatively high anti-overturning stability.

3.The prime mover has the power to meet other requirements, and the braking device should provide the necessary braking torque.

Features

1.It is a structural form welded with angle steel or I-beam, with the advantages of low cost, light weight, and good wind resistance.Suitable for sites with low safety requirements and small lifting capacity.

2.However, due to the large number of welding points and the inherent defects of the truss, the truss beam also has disadvantages such as large deflection, small stiffness, relatively low reliability, and the need for frequent inspection of welding points.

Technical Data

|

Capacity |

t |

5 |

10 |

16 |

||||||||||||

|

Span |

S(m) |

12 |

16 |

20 |

24 |

12 |

16 |

20 |

24 |

30 |

12 |

16 |

20 |

24 |

30 |

|

|

Lifting height |

m |

6/9 |

6/9 |

6/9 |

||||||||||||

|

Wheel Diameter |

mm |

Φ270 |

Φ400 |

Φ400 |

Φ600 |

Φ500 |

Φ600 |

|||||||||

|

Lifting speed |

m/min |

8 8/0.8 |

7 0.7/7 |

3.5 |

||||||||||||

|

Travelling Speed |

m/min |

20 |

20 |

20 |

||||||||||||

|

Working Class |

|

A3 |

A3 |

A5 |

||||||||||||

|

Power Supply |

|

380V 50HZ |

380V 50HZ |

380V 50HZ |

||||||||||||

Spare Parts

Main beam

The main beam is a box beam or H-beam structure, welded and formed from steel plates. The steel plate material is domestic steel (Q235B). The vertical winding is in accordance with Chinese national standards. All steel plates are subjected to shot blasting pre-treatment to achieve Sa2.5 level standardization. Before welding, the steel plates are carefully inspected and cleaned, usually by automatic welding machines (MIG or semi-automatic welding).

Ground beam

The lower beam is also a box-shaped structure, mainly composed of cover plates, webs, ribs, flange supports and other parts. The production process is similar to that of the main beam and other box beams. After the lower beam structure is completed, the bent plates are assembled according to the drawing. The flange support is welded to the lower beam after the lower beam is made to ensure the level of the flange surface. When the lower beam and the leg are assembled, the flange on the flange made on the leg is welded to the leg. The appearance quality and geometric dimensions of the lower crossbeam after production meet the requirements of the standard GB14406-93.

Electric hoist

The electric hoist will do dynamic and static load tests, as well as ascending and descending pressure tests. The baking paint process is used to enhance the adhesion of the paint film and improve the appearance quality. The assembly line ensures product quality.

Crane remote control

Industrial wireless remote control is a remote wireless remote control device specifically used to control construction machinery or industrial equipment.

Crane control box

The surface of the control box has undergone anti-corrosion treatment Reasonable layout for easy maintenance Protection level IP55 Environmental temperature:<45 ° C, humidity<90%

Keywords

MH type electric hoist gantry crane

Contact Us

Classification