Description

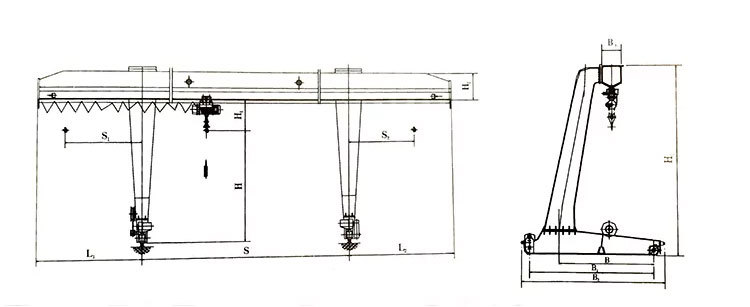

L Type electric hoist gantry crane match with CD1/ MD1, HC type Electric Wire rope hoist, to lifting and transporting the heavy materials, mainly use indoors and outdoors. In order to expand the scope of the crane operation, the main girder can extend to one side or both sides to extend the leg to form a cantilever. It is also possible to extend the operation scope of the crane by lifting and lifting the boom with the boom.

Working Condition

1. Metal structures and mechanical parts should have sufficient strength, stiffness and buckling resistance.

First of all, it is required that parts and metal structures are not damaged after being loaded. For parts such as steel wire ropes with complex stress states, static strength calculations are usually performed with a higher safety factor based on the main load and main deformation form. It must also be required that the deformation of the component under load is within the allowable range, that is, it should have sufficient stiffness.

2. The whole machine must have relatively high anti-overturning stability.

The prime mover has the power to meet other requirements, and the braking device should provide the necessary braking torque.

3. The prime mover has the power to meet other requirements, and the braking device should provide the necessary braking torque.

Features

1.L Type Electric Hoist Gantry Crane has a simple structure, convenient manufacturing and installation, and small weight.

2.The main beam of the L-shaped gantry crane is mostly a biased rail box frame structure. Compared with the double main beam gantry crane, the overall stiffness is weaker. Therefore, when the lifting capacity Q = 50t and the span S = 3 5m, this form can be used.

3.This machine prohibits lifting molten metals and flammable and explosive materials. According to user requirements, it can also be made into a single end overhanging or non overhanging structure.

4.The working environment temperature of this machine is between 35 ℃ and 20 ℃, and the power supply is three-phase AC 50Hz. 380V.

Technical Data

|

Lifting Weight |

t |

5 |

10 |

|||||||||

|

Span |

m |

18 |

22 |

26 |

30 |

35 |

18 |

22 |

26 |

30 |

35 |

|

|

Lift height |

10 |

11 |

10 |

11 |

||||||||

|

Working class |

A5 |

A5 |

||||||||||

|

|

Lifting |

m/min |

11.3 |

8.5 |

||||||||

|

Handcart |

35.6 |

40.12 |

||||||||||

|

Cart travel |

37.5 |

40 |

39.5 |

40 |

||||||||

|

|

Lift |

Type/ |

YZR180L-8/13 |

YZR180L-6/17 |

||||||||

|

Handcart |

YZR112M-6/1.8 |

YZR132M₂-6/4 |

||||||||||

|

Cart travel |

YZR160M₂-6/8.5×2 |

YZR160L-6/13×2 |

YZR160M₂-6/ 8.5×2 |

YZR160L-6/13×2 |

||||||||

|

|

Handcart |

t |

2.93 |

2.94 |

2.95 |

4.23 |

4.27 |

|||||

|

Total Weight |

32.3 |

34.7 |

41 |

48.9 |

51.9 |

41.3 |

45 |

48.6 |

58.3 |

62.3 |

||

|

Max.Wheel pressure |

KN |

160 |

166 |

185 |

213 |

233 |

225 |

236 |

239 |

286 |

298 |

|

|

Steel track |

43kg/m |

43kg/m |

||||||||||

Spare Parts

Main beam

The main beam is a box beam or H-beam structure, welded and formed from steel plates. The steel plate material is domestic steel (Q235B). The vertical winding is in accordance with Chinese national standards. All steel plates are subjected to shot blasting pre-treatment to achieve Sa2.5 level standardization. Before welding, the steel plates are carefully inspected and cleaned, usually by automatic welding machines (MIG or semi-automatic welding).

Ground beam

The lower beam is also a box-shaped structure, mainly composed of cover plates, webs, ribs, flange supports and other parts. The production process is similar to that of the main beam and other box beams. After the lower beam structure is completed, the bent plates are assembled according to the drawing. The flange support is welded to the lower beam after the lower beam is made to ensure the level of the flange surface. When the lower beam and the leg are assembled, the flange on the flange made on the leg is welded to the leg. The appearance quality and geometric dimensions of the lower crossbeam after production meet the requirements of the standard GB14406-93.

Electric hoist

The lifting capacity of electric hoists is generally 0.3-80 tons, and the lifting height is 3-30 meters. Composed of an electric motor, transmission mechanism, and a drum or sprocket, it is divided into two types: wire rope electric hoist and ring chain electric hoist. The electric chain hoist is divided into two types: imported and domestically produced; The wire rope electric hoist is divided into single speed lifting and double speed lifting; small electric hoist, multifunctional hoist.

Crane remote control

Industrial wireless remote control is a remote wireless remote control device specifically used to control construction machinery or industrial equipment.

Crane control box

The surface of the control box has undergone anti-corrosion treatment Reasonable layout for easy maintenance Protection level IP55 Environmental temperature:<45 ° C, humidity<90%

Keywords

L Type Electric Hoist Gantry Crane

Contact Us

Classification