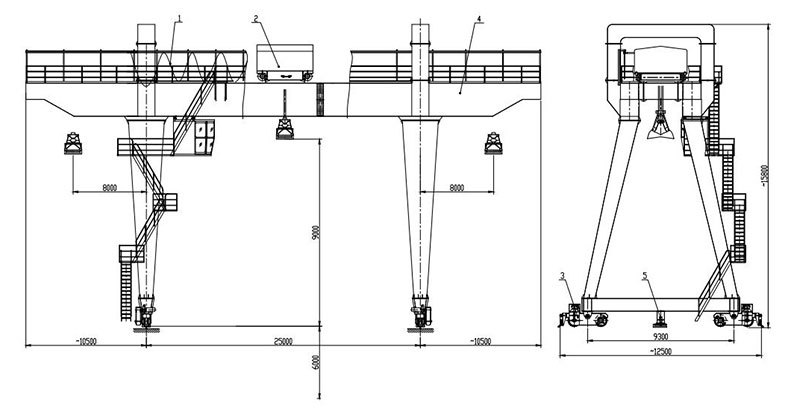

Description

MZ Type Double-beam Grab Gantry Crane are mainly used in conjunction with bridge cranes, port cranes, and winches. They are widely used in ports, power plants, docks, chemical industries, etc. to grab various types of loose accumulations, such as ore, coal, slag, etc. Carry out loading, unloading, light stacking, feeding and other operations. The gantry grab crane unloads bulk cargo such as coal, ore and phosphate from the cargo hold into a hopper, and then unloads it via a conveyor belt to the storage yard or loading platform. Lifting equipment grab bridge crane is specially designed for bulk and granular materials. Conventional configuration of gantry grab crane: using driver’s cab control, separated type and closed type. Each mechanism adopts a wire-wound lifting motor and resistor speed regulation. Gantry grab crane working levels: A6, A7, working environment 200C~+400C. This model is not recommended for use in working environments with explosion-proof and insulation requirements.

Working Condition

1. Metal structures and mechanical parts should have sufficient strength, stiffness and buckling resistance.

First of all, it is required that parts and metal structures are not damaged after being loaded. For parts such as steel wire ropes with complex stress states, static strength calculations are usually performed with a higher safety factor based on the main load and main deformation form. It must also be required that the deformation of the component under load is within the allowable range, that is, it should have sufficient stiffness.

2. The whole machine must have relatively high anti-overturning stability.

3. The prime mover has the power to meet other requirements, and the braking device should provide the necessary braking torque.

Features

1.MZ Type Double-beam Grab Gantry Crane is suitable for handling loose particles such as ore, limestone, ore powder, coke, coal sand, etc. in warehouses and workshops of metallurgical, cement, chemical, and other enterprises indoors, outdoors, and in fixed spans.

2.This product consists of five parts: box shaped bridge, crane operating mechanism, trolley, grab, and electrical equipment, all of which are operated inside the control room. The retrieval device is a double drum four rope grab, with a simple structure and reliable operation.

3.The grab bucket can be opened and closed at any height. When the material particles are grabbed below 100mm, the effect is good and the production efficiency is high. When the material particles are dried up to 200mm, a toothed grab bucket needs to be selected.

Technical Data

|

Lifting Weight(t) |

20/10 |

32/10 |

||||||||||||

|

Span(m) |

18 |

22 |

26 |

30 |

35 |

22 |

26 |

|||||||

|

Lifting height(m) |

Main |

10.5 |

11.5 |

|||||||||||

|

|

Aux |

11 |

12 |

|||||||||||

|

Working Class |

A5 |

A5 |

||||||||||||

|

Speed(m/min) |

Lift |

Main |

7.2 |

7.5 |

||||||||||

|

|

|

Aux |

10.4 |

10.4 |

||||||||||

|

|

Travel |

Handcart |

44.5 |

41.9 |

||||||||||

|

|

|

Cart |

38 |

36 |

40 |

|||||||||

|

Motor |

Lift |

Main |

YZR225M-8/26 |

YZR280S-10/42 |

||||||||||

|

|

|

Aux |

YZR200L-6/4×2 |

YZR200L-6/26 |

||||||||||

|

|

Travel |

Handcart |

YZR132M2-6/4×2 |

YZR132M1-6/6.3×2 |

||||||||||

|

|

|

Cart |

YZR160L-6/13×2 |

YZR160M2-6/8.5×4 |

YZR160M2-6/8.5×4 |

|||||||||

|

Weight(t) |

Handcart |

12 |

16 |

|||||||||||

|

|

Total weight |

79 |

85 |

96 |

110 |

120 |

95 |

108 |

||||||

|

Max. Wheel Pressure |

376 |

389 |

208 |

223 |

240 |

324 |

334 |

|||||||

|

Steel track |

50kg/m QU70 |

|||||||||||||

|

Power supply |

AC 3Ph 380V 50Hz(can custom made) |

|||||||||||||

Spare Parts

Main beam

The main beam is a box beam or H-beam structure, welded and formed from steel plates. The steel plate material is domestic steel (Q235B). The vertical winding is in accordance with Chinese national standards. All steel plates are subjected to shot blasting pre-treatment to achieve Sa2.5 level standardization. Before welding, the steel plates are carefully inspected and cleaned, usually by automatic welding machines (MIG or semi-automatic welding).

Ground beam

The lower beam is also a box-shaped structure, mainly composed of cover plates, webs, ribs, flange supports and other parts. The production process is similar to that of the main beam and other box beams. After the lower beam structure is completed, the bent plates are assembled according to the drawing. The flange support is welded to the lower beam after the lower beam is made to ensure the level of the flange surface. When the lower beam and the leg are assembled, the flange on the flange made on the leg is welded to the leg. The appearance quality and geometric dimensions of the lower crossbeam after production meet the requirements of the standard GB14406-93.

Grab

Grab bucket refers to a specialized tool used by a crane to grab dry and loose goods. The container space is composed of two or more bucket shaped jaw plates that can be opened and closed together. When loading, the jaw plates are closed in the material pile, and the material is grabbed into the container space. When unloading, the jaw plates open in a suspended state on the material pile, and the material is scattered on the pile. The opening and closing of the jaw plates are generally controlled by the steel wire rope of the lifting mechanism of the crane. Grab bucket operation does not require heavy physical labor, can achieve high loading and unloading efficiency and ensure safety, and is the main dry bulk loading and unloading tool in ports. According to the type of homework goods, they can be divided into ore grab, coal grab, grain grab, wood grab, etc.

Crane remote control

Industrial wireless remote control is a remote wireless remote control device specifically used to control construction machinery or industrial equipment.

Crane control box

The surface of the control box has undergone anti-corrosion treatment Reasonable layout for easy maintenance Protection level IP55 Environmental temperature:<45 ° C, humidity<90%

Keywords

MZ Type Double-beam Grab Gantry Crane

Contact Us

Classification