Description

KBK flexible cranes include various forms of cranes such as monorail, single beam, double beam, and telescopic beam, with a lifting capacity of 0.125t-2t. They have a wide range of applications, especially suitable for modern production conveyor lines. The lifting system is lightweight, flexible, reliable, and stable, with all components using standard modules, ensuring large-scale and high-quality production, and easy maintenance in the later stage. KBK flexible tracks and various standard modules can be connected by bolts, which is easy to install, cost-effective, and can greatly save factory space and area, thereby saving costs, improving efficiency, and further increasing enterprise benefits.

Working Condition

1. Rated lifting capacity: The rated lifting capacity of a crane is its maximum load-bearing capacity and overloading is not allowed. The rated lifting capacity includes the lifted load and additional loads (such as lifting equipment, ropes, etc.)

2. Applicable environment: KBK flexible combination suspension crane is suitable for general workshops, warehouses, and places where materials weighing less than 2 tons need to be lifted and transported. The ambient temperature is required to be between -20 ° C and 70 ° C. For cranes with ambient temperatures exceeding this range, outdoor and corrosive gas (liquid) environments, special protective measures should be taken.

3. Installation conditions: The altitude of the installation and use location of the crane should not exceed 2000 meters, and it should usually work indoors

4. Technical parameters: The maximum load-bearing capacity of KBK flexible combination crane is generally 2000 kilograms, and the maximum span of the main beam can reach 9 meters. Some models have a span of up to 8 meters and a lifting capacity of up to 1000 kilograms

Features

1.The flexible KBK crane consists of supporting columns, attached beams, running rails, main beams, electric hoists, power supply systems, etc. Its design concept is to provide a lightweight and flexible way of transportation.

2.The characteristic of flexible KBK is easy installation, and users can quickly deploy or adjust the lifting system within the work area according to their actual needs.

3.Its load capacity can reach 2000kg, and the main beam can reach 9 meters, suitable for lifting materials on various planes. Due to its light weight and flexible operation, the flexible KBK can achieve efficient material handling, greatly improving the production efficiency and space utilization of the work area.

Technical Data

|

Capacity(kg) |

125 |

250 |

500 |

1000 |

2000 |

|

|

Span(mm) |

LK |

8500 |

7500 |

6000 |

5000 |

4000 |

|

Total length (mm) |

L |

9000 |

8000 |

7000 |

6000 |

5000 |

|

height(mm) |

H |

808 |

878 |

948 |

1100 |

1200 |

|

h |

335 |

335 |

335 |

365 |

365 |

|

|

Hanging(mm) |

L1 |

470 |

470 |

525 |

585 |

645 |

|

L2 |

100 |

100 |

100 |

250 |

250 |

|

|

Lifting Height(m) |

1~6 |

|||||

|

Operating mechanism |

Lifting Speed(m/min) |

8/2 |

7.8/2.6 |

7.2/2.4 |

6.3/2.1 |

5.4/1.8 |

|

Trolley |

Manual/Electric |

|||||

|

Crane |

Manual/Electric |

|||||

|

Whole machine working grade |

M3 |

|||||

Spare Parts

Track system

The track system is the foundation of the KBK combination crane, carrying the weight of the entire crane and the weight of the lifted materials. It is responsible for providing guidance and support for the movement of the crane, ensuring that the crane maintains a stable and smooth state during operation. The track system is usually composed of steel rails, track supports, track connectors, etc. These components are precisely designed and strictly manufactured to withstand high loads and long-term use, ensuring the reliability and safety of the crane.

Lifting mechanism

The lifting mechanism is the core part of the KBK combination crane, mainly responsible for the lifting and lowering operations of materials. It usually includes components such as electric hoists, pulley systems, steel wire ropes, etc. The electric hoist is driven by an electric motor, and the pulley system drives the steel wire rope to achieve the lifting and lowering of materials. The design of the pulley system can reduce the wear and tension of the steel wire rope, and improve the service life of the crane. The steel wire rope is responsible for connecting the electric hoist and materials, bearing the weight of the materials. The design of the lifting mechanism takes into account factors such as efficiency, safety, and stability, and can meet different working environments and lifting needs.

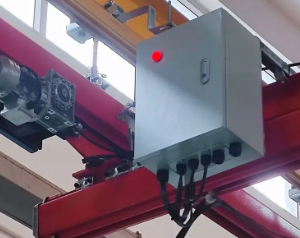

Electrical control system

The electrical control system is the “brain” of the KBK modular crane, responsible for controlling all actions of the crane, including lifting, lowering, moving, etc. It usually consists of control cabinets, motors, sensors, cables, etc. The control cabinet is equipped with various electrical components and controllers, which can receive operation instructions and control the action of the motor. The motor is the actuator of the electrical control system, which drives the movement of the crane through rotation. Sensors are responsible for detecting the status of the crane and the position of materials, providing real-time data for the electrical control system. Cables are responsible for transmitting electrical energy and control signals, ensuring the normal operation of the electrical control system. The efficient, precise, and safe characteristics of the electrical control system provide strong guarantees for the stable operation of the crane.

Keywords

Flexible KBK Crane

Contact Us

Classification